Coatings Equipment

Electroplating additive

Sewage treatment equipment

Dedusting equipment

Dust removal system

Waste gas treatment equipment

RTO

RCO

Other testing instruments

Filter / filter cloth / standard screen mesh

Water tank

Oven

Electronic balance

Environmental testing instrument

Hygrothermal / salt spray / thermal aging

Friction resistance

Paint film wear meter / wood wear tester

Analysis instrument

Gas chromatograph

Other spraying auxiliary equipment

Conveying equipment

Electrostatic spraying high voltage power supply

Lacquer box

Program control system

Pretreatment equipment

Ultrasonic cleaner

Color measurement

Gloss Meters

Spectrophotometer

management system

ERP management system

Automatic control system

Complete set of equipment

Integrated coating equipment

auxiliary equipment

gear pump

Other auxiliary equipment

Automatic palletizing machine

Automatic capper

Pneumatic diaphragm pump

Storage tank

tinting system

Transport pump

Injection molding equipment

Spray molding line

Electrophoretic equipment

Electrophoretic coating line

Spray painting equipment

Dustless baking room

Dustless spray booth

Airless spray gun

Powder spraying equipment

Spraying equipment

Air spray

Electrostatic spraying

Airless spraying

Robot

Ordinary roller coater

Ω-type paint spraying machine

Omega paint spraying machine

Manual spray gun

Coating detection equipment

Automatic coating device

applicator

Hardness testing equipment

Hardness testing standard pencil

Automatic scratch tester

Viscosity testing equipment

Other viscosity measuring instruments

rotary viscosimeter

Viscosity cup

Filling equipment

Automatic production assembly line

Filling System

Filling machine

Paint Barrel

Production equipment

Dispersion machine

Ball mill

Painting tank

Mixer

filter

Vibration sieve

Reaction kettle

Blender

Lapping machine

Sand mill

Emulsification machine

Painting equipment

Coating production line

Painting line

Marking Machine

Coating Plant

Embossing Equipment

Flocking Equipment

Label Printing

Metallization Equipment

Plastic and Rubber Printing

In Mold Labeling Equipment

Other Machinery and Equipment For Decoration, Printing, and Labeling

Yangtao Technology's extruded film thickness gauge is applied in the plastic film and sheet industry. Modern production processes require faster and more accurate quality control technology to ensure overall product quality. Our company has introduced technology from SOTER, an Italian company, and collaborated with top research institutes to develop and produce the PSD-500 online thickness (gram weight) detection system. This system is a detection device that can detect and provide real-time feedback on the thickness or weight of various films, fabrics and non-woven fabrics, coated fabrics, composite materials, and other products. TAG1TAG2 online real-time detection and data statistical analysis can improve product quality, reduce production costs, and create conditions for automated production. The TAG3TAG4 system mainly consists of a thickness (gram weight) sensor, an "O" - shaped ("C" - shaped) scanning frame, an electrical control system, a computer cabinet, and detection software. Working principle of TAG5TAG6TAG7TAG8: The TAG9TAG10PSD-500 X-ray online detection system measures thickness or weight based on the principle of intensity attenuation when X-rays penetrate the measured object, that is, measures the X-ray energy absorbed by the measured object, and determines the thickness (weight) of the measured object based on the energy value of the X-ray. TAG11TAG12 formula: I=Ioe - μ ρ d. TAG13TAG14 formula:& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; I - X-ray energy after passing through the tested object; TAG15TAG16Io--& nbsp; & nbsp; The X-ray energy before passing through the tested object; TAG17TAG18 μ - Linear absorption coefficient of the analyte for X-rays; TAG19TAG20 ρ - density of the tested substance; TAG21TAG22d --& nbsp; The thickness (in grams) of the tested object. When μ, Io, and ρ are constant, I is only a function of the thickness (gram weight) d of the measured material, so measuring I can determine the thickness (gram weight) d. TAG25TAG26 Product advantages: TAG27TAG28 Ø& nbsp; The X-ray source has low energy output and does not produce any radiation when the power is turned off. TAG29TAG30Ø& nbsp; The equipment has been exempted by the environmental protection department, and users do not need to handle application and filing procedures, making it easy to use. TAG31TAG32Ø& nbsp; Capable of flexibly adapting to various industries with diverse varieties, complex processes, and strict quality requirements. TAG33TAG34Ø& nbsp; It has position compensation function. TAG35TAG36Ø& nbsp; High cleanliness design will not cause any pollution to the tested product. TAG37TAG38Ø& nbsp; Mechanical error of upper and lower probes: ± 0.03mm; scanning positioning accuracy: 1mm; measurement speed: 2500 measurement values/second. TAG39TAG40TAG41 PSD-500

Yangtao Technology's extruded film thickness gauge is applied in the plastic film and sheet industry. Modern production processes require faster and more accurate quality control technology to ensure overall product quality. Our company has introduced technology from SOTER, an Italian company, and collaborated with top research institutes to develop and produce the PSD-500 online thickness (gram weight) detection system. This system is a detection device that can detect and provide real-time feedback on the thickness or weight of various films, fabrics and non-woven fabrics, coated fabrics, composite materials, and other products. TAG1TAG2 online real-time detection and data statistical analysis can improve product quality, reduce production costs, and create conditions for automated production. The TAG3TAG4 system mainly consists of a thickness (gram weight) sensor, an "O" - shaped ("C" - shaped) scanning frame, an electrical control system, a computer cabinet, and detection software. Working principle of TAG5TAG6TAG7TAG8: The TAG9TAG10PSD-500 X-ray online detection system measures thickness or weight based on the principle of intensity attenuation when X-rays penetrate the measured object, that is, measures the X-ray energy absorbed by the measured object, and determines the thickness (weight) of the measured object based on the energy value of the X-ray. TAG11TAG12 formula: I=Ioe - μ ρ d. TAG13TAG14 formula:& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; I - X-ray energy after passing through the tested object; TAG15TAG16Io--& nbsp; & nbsp; The X-ray energy before passing through the tested object; TAG17TAG18 μ - Linear absorption coefficient of the analyte for X-rays; TAG19TAG20 ρ - density of the tested substance; TAG21TAG22d --& nbsp; The thickness (in grams) of the tested object. When μ, Io, and ρ are constant, I is only a function of the thickness (gram weight) d of the measured material, so measuring I can determine the thickness (gram weight) d. TAG25TAG26 Product advantages: TAG27TAG28 Ø& nbsp; The X-ray source has low energy output and does not produce any radiation when the power is turned off. TAG29TAG30Ø& nbsp; The equipment has been exempted by the environmental protection department, and users do not need to handle application and filing procedures, making it easy to use. TAG31TAG32Ø& nbsp; Capable of flexibly adapting to various industries with diverse varieties, complex processes, and strict quality requirements. TAG33TAG34Ø& nbsp; It has position compensation function. TAG35TAG36Ø& nbsp; High cleanliness design will not cause any pollution to the tested product. TAG37TAG38Ø& nbsp; Mechanical error of upper and lower probes: ± 0.03mm; scanning positioning accuracy: 1mm; measurement speed: 2500 measurement values/second. TAG39TAG40TAG41 PSD-500

The X-ray thickness detection system ensures high-precision online dynamic measurement with PSD-500

The X-ray thickness detection system ensures high-precision online dynamic measurement with PSD-500

PSC MCT series online moisture analyzer from the United States, with precise detection. Welcome to consult MCT50/56

PSC MCT series online moisture analyzer from the United States, with precise detection. Welcome to consult MCT50/56

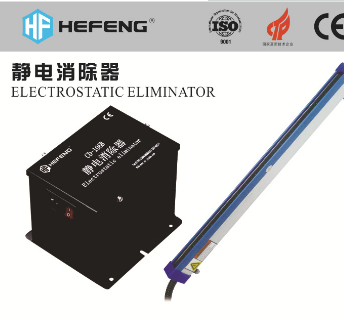

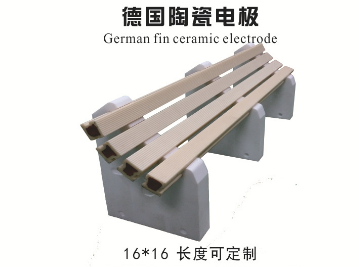

【 Imported from Germany 】 Square 12 * 16 Ceramic Rod for Corona Machine 【 Hefeng Machinery 】

【 Imported from Germany 】 Square 12 * 16 Ceramic Rod for Corona Machine 【 Hefeng Machinery 】