Search Filter ×

Product Category

Plastic And Rubber Machinery And Equipment

Injection Molding

Rubber Injection Molding

Thermosetting Plastic Injection Molding

General Injection Molding

Other Injection Molding

Manufacturer

With the rapid development of electronic products and the automotive industry, in order to adapt to the trends of high, new, and cutting-edge development, customers have increasingly high precision requirements for electronic components and automotive parts. After years of research and development, AGCO has launched a vertical hydraulic electric composite injection molding machine that can combine the stability and low cost of traditional hydraulic injection molding machines with the high ejection accuracy of electric injection molding machines. It has won the favor of well-known companies such as Huawei suppliers, Amphenol in the United States, and INTERPLEX in the United States! Product advantages: Save energy consumption and reduce energy loss in the process of converting electrical energy into hydraulic energy; Action synchronization can achieve synchronous action between melt adhesive and mold opening, or between melt adhesive and mold support (with the addition of self-locking nozzles); This model combines the stability and maturity of the hydraulic system with the high precision of rapid injection and measurement of the electric system, high repeatability of injection (0.01mm), and injection speed ≥ 300mm/s to improve accuracy; During machine production and operation, the noise level will be reduced by 10dB (decibels), which is much lower than the national minimum standard of 90dB. Suitable products: Suitable for automotive parts manufacturing, electronic precision components, communication industry products, aviation industry products, medical supplies, etc.

With the rapid development of electronic products and the automotive industry, in order to adapt to the trends of high, new, and cutting-edge development, customers have increasingly high precision requirements for electronic components and automotive parts. After years of research and development, AGCO has launched a vertical hydraulic electric composite injection molding machine that can combine the stability and low cost of traditional hydraulic injection molding machines with the high ejection accuracy of electric injection molding machines. It has won the favor of well-known companies such as Huawei suppliers, Amphenol in the United States, and INTERPLEX in the United States! Product advantages: Save energy consumption and reduce energy loss in the process of converting electrical energy into hydraulic energy; Action synchronization can achieve synchronous action between melt adhesive and mold opening, or between melt adhesive and mold support (with the addition of self-locking nozzles); This model combines the stability and maturity of the hydraulic system with the high precision of rapid injection and measurement of the electric system, high repeatability of injection (0.01mm), and injection speed ≥ 300mm/s to improve accuracy; During machine production and operation, the noise level will be reduced by 10dB (decibels), which is much lower than the national minimum standard of 90dB. Suitable products: Suitable for automotive parts manufacturing, electronic precision components, communication industry products, aviation industry products, medical supplies, etc.

Negotiable

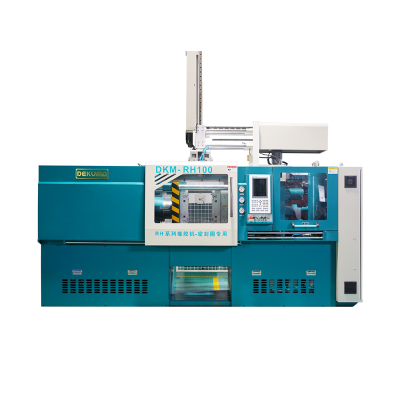

Have you encountered difficulties in recruiting and retaining employees? Are you troubled by the continuous increase in raw material and electricity prices, while the selling price of the product cannot increase? Let's turn our attention to the latest generation DKM-H100 horizontal rubber seal ring machine launched by Dekemo on the right-hand side. It can at least help you solve the following problems: improve efficiency, solve the headache of recruitment and retention difficulties; The horizontal mold locking mechanism combined with automated brush design enables automated demolding of products and automatic cleaning of molds. Compared with traditional equipment, it can reduce labor by 80% and significantly improve production efficiency. The built-in automatic system can significantly reduce labor intensity, allowing workers to reduce high-temperature demolding and mold cleaning work, significantly improving the working environment, and helping enterprises better retain skilled workers. Material saving, energy-saving, and more worry free; Equipping with a cold runner system can significantly reduce the amount of material at the water outlet. Compared with conventional equipment, the servo control system can save more than 40% energy and significantly improve the product qualification rate. What reason do you have to refuse a device that can create greater profits for you and workers are eager to use it? Dekomo, German Gene, China Intelligent Manufacturing

Have you encountered difficulties in recruiting and retaining employees? Are you troubled by the continuous increase in raw material and electricity prices, while the selling price of the product cannot increase? Let's turn our attention to the latest generation DKM-H100 horizontal rubber seal ring machine launched by Dekemo on the right-hand side. It can at least help you solve the following problems: improve efficiency, solve the headache of recruitment and retention difficulties; The horizontal mold locking mechanism combined with automated brush design enables automated demolding of products and automatic cleaning of molds. Compared with traditional equipment, it can reduce labor by 80% and significantly improve production efficiency. The built-in automatic system can significantly reduce labor intensity, allowing workers to reduce high-temperature demolding and mold cleaning work, significantly improving the working environment, and helping enterprises better retain skilled workers. Material saving, energy-saving, and more worry free; Equipping with a cold runner system can significantly reduce the amount of material at the water outlet. Compared with conventional equipment, the servo control system can save more than 40% energy and significantly improve the product qualification rate. What reason do you have to refuse a device that can create greater profits for you and workers are eager to use it? Dekomo, German Gene, China Intelligent Manufacturing

Negotiable