Plastic And Rubber Machinery And Equipment

Blow Molding

Extrusion Blow Molding

Injection Blow Molding

Injection-stretch-blow molding machine

Other Blow Molding Machines

Other Plastic Processing

Calender

Rapid Prototyping

Other Rubber Processing

Sheet Casting

Resin Enhancement Equipment

Open Mold Casting

Filament Winding

Injection Molding

Rubber Injection Molding

Thermosetting Plastic Injection Molding

General Injection Molding

Other Injection Molding

Post processing machinery

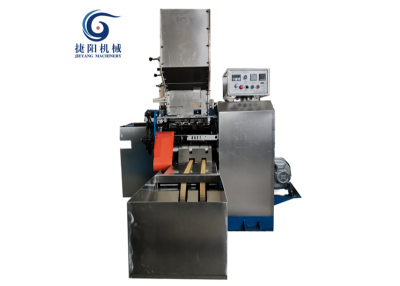

Bag making equipment

Bending machine, folding machine and cutting machine

Trimming flash machine

Milling machine

Corrugated tube forming machine

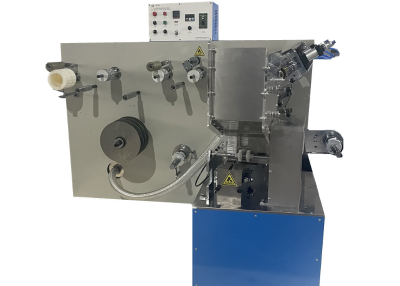

Slitting rewinding machine

Slitter, peeling machine

Thermoforming machine

Vulcanizing Machine

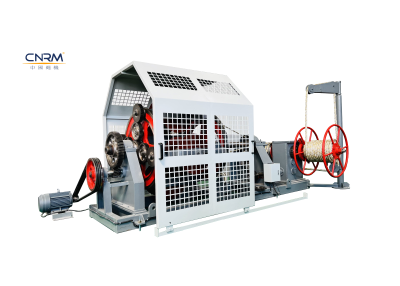

Winding equipment

Plastic Weaving Machine

Other Post-Processing Machinery

Welding machine

Hot gas welding machine

Hot plate welding machine

Other Welding Machines

Measuring and experimental equipment

measuring equipment

Experimental equipment

Other Measuring and Testing Equipment

spare parts

Roller, barrel,drum

Blade, scraper

Nozzles and nozzles

Hydraulic components

screw

Other Components

Pre processing and recycling machinery

Mixer

Pelletizer

Screen changer / melt filter

Plastic particle filter, classifier and dust removal system

Crushing equipment (crusher, crusher, shredder, vane granulator)

Double Roll Plastic Mixer

Other Pre-Processing and Recycling Machinery and Equipment

Abrasives

extrusion die

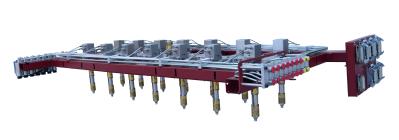

hot runner system

Injection mold and compression mold

Mold cleaning equipment

Mold standard parts

Other molds

Integrated automation equipment

Sensor, driver, control system

Assembly system

Conveyor and conveying system

Quantitative feeding device and metering device

Loading and unloading device

Silo discharge device

Other Comprehensive Automation Equipment

auxiliary equipment

Air compressor

Degassing systems

Gas assisted / water assisted injection equipment

Melt pump

Other Auxiliary Equipment

press

Plastic press and die casting press

Other presses

Extruders and extrusion lines

Single screw extruder

Double screw extruder

Blowing film extrusion line

Flat extrusion film and sheet extrusion line

Hose extrusion line

Rubber extrusion line

Other extruders

Other extrusion lines

Plunger Extruder

Digital System

Software Maintenance

Other Digital Systems

The HB300 series four axis cast PE winding film/grass film production line (1000-4000mm)

The HB300 series four axis cast PE winding film/grass film production line (1000-4000mm)

Based on years of experience in the application of hot runner systems, Nanfeng has developed locally produced hot runner systems to meet the cost, delivery time, and quality requirements of our customers. We have established rigorous quality objectives for our developed hot runner products, aligning with leading brands in the industry in terms of design, material selection, and production control. We are committed to providing users with cost-effective and high-quality products. The Nanfeng hot runner is divided into three series: Q2, Q3, and Q4, corresponding to different injection molding requirements and nozzle installation diameters. Q2 corresponds to a small injection volume and installation space, and is also widely used in packaging applications. Q3 corresponds to general injection molding requirements and is suitable for high injection pressure applications (thin-walled). Each series of Nanfeng hot runner nozzles can also choose different injection port methods to meet various injection molding requirements. Based on our years of application experience, the design of Nanfeng hot runner takes functionality and practicality as the main considerations, and is suitable for most plastics. We insist on using high-quality raw materials to ensure the quality of the system. All electric heating elements are imported from Europe and America. The production process has our rigorous control, and all products meet our quality standards. Q4 corresponds to larger requirements for injection molded products.

Based on years of experience in the application of hot runner systems, Nanfeng has developed locally produced hot runner systems to meet the cost, delivery time, and quality requirements of our customers. We have established rigorous quality objectives for our developed hot runner products, aligning with leading brands in the industry in terms of design, material selection, and production control. We are committed to providing users with cost-effective and high-quality products. The Nanfeng hot runner is divided into three series: Q2, Q3, and Q4, corresponding to different injection molding requirements and nozzle installation diameters. Q2 corresponds to a small injection volume and installation space, and is also widely used in packaging applications. Q3 corresponds to general injection molding requirements and is suitable for high injection pressure applications (thin-walled). Each series of Nanfeng hot runner nozzles can also choose different injection port methods to meet various injection molding requirements. Based on our years of application experience, the design of Nanfeng hot runner takes functionality and practicality as the main considerations, and is suitable for most plastics. We insist on using high-quality raw materials to ensure the quality of the system. All electric heating elements are imported from Europe and America. The production process has our rigorous control, and all products meet our quality standards. Q4 corresponds to larger requirements for injection molded products.