Plastic And Rubber Machinery And Equipment

Blow Molding

Extrusion Blow Molding

Injection Blow Molding

Injection-stretch-blow molding machine

Other Blow Molding Machines

Other Plastic Processing

Calender

Rapid Prototyping

Other Rubber Processing

Sheet Casting

Resin Enhancement Equipment

Open Mold Casting

Filament Winding

Injection Molding

Rubber Injection Molding

Thermosetting Plastic Injection Molding

General Injection Molding

Other Injection Molding

Post processing machinery

Bag making equipment

Bending machine, folding machine and cutting machine

Trimming flash machine

Milling machine

Corrugated tube forming machine

Slitting rewinding machine

Slitter, peeling machine

Thermoforming machine

Vulcanizing Machine

Winding equipment

Plastic Weaving Machine

Other Post-Processing Machinery

Welding machine

Hot gas welding machine

Hot plate welding machine

Other Welding Machines

Measuring and experimental equipment

measuring equipment

Experimental equipment

Other Measuring and Testing Equipment

spare parts

Roller, barrel,drum

Blade, scraper

Nozzles and nozzles

Hydraulic components

screw

Other Components

Pre processing and recycling machinery

Mixer

Pelletizer

Screen changer / melt filter

Plastic particle filter, classifier and dust removal system

Crushing equipment (crusher, crusher, shredder, vane granulator)

Double Roll Plastic Mixer

Other Pre-Processing and Recycling Machinery and Equipment

Abrasives

extrusion die

hot runner system

Injection mold and compression mold

Mold cleaning equipment

Mold standard parts

Other molds

Integrated automation equipment

Sensor, driver, control system

Assembly system

Conveyor and conveying system

Quantitative feeding device and metering device

Loading and unloading device

Silo discharge device

Other Comprehensive Automation Equipment

auxiliary equipment

Air compressor

Degassing systems

Gas assisted / water assisted injection equipment

Melt pump

Other Auxiliary Equipment

press

Plastic press and die casting press

Other presses

Extruders and extrusion lines

Single screw extruder

Double screw extruder

Blowing film extrusion line

Flat extrusion film and sheet extrusion line

Hose extrusion line

Rubber extrusion line

Other extruders

Other extrusion lines

Plunger Extruder

Digital System

Software Maintenance

Other Digital Systems

【 Imported from Germany 】 Square 15 * 15 Ceramic Rod for Corona Machine 【 Hefeng Machinery 】

【 Imported from Germany 】 Square 15 * 15 Ceramic Rod for Corona Machine 【 Hefeng Machinery 】

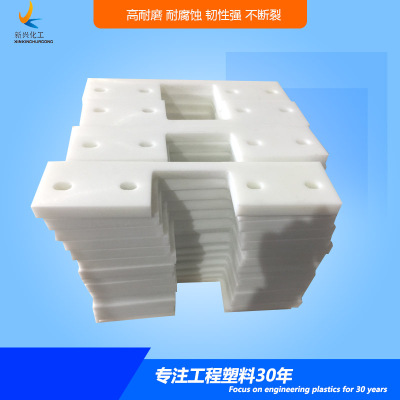

Production of ultra-high molecular weight polyethylene scraper with self-lubricating and wear-resistant properties

Production of ultra-high molecular weight polyethylene scraper with self-lubricating and wear-resistant properties

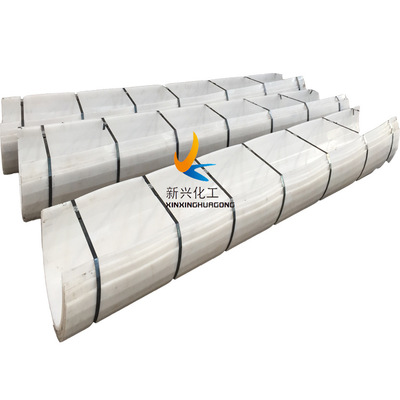

Polymer spiral conveyor lining polymer U-shaped lining plate conveyor wear-resistant lining plate

Polymer spiral conveyor lining polymer U-shaped lining plate conveyor wear-resistant lining plate

Working principle of reciprocating single screw PVC cable material mixing and extrusion granulator

Working principle of reciprocating single screw PVC cable material mixing and extrusion granulator

600 type pearl cotton hot melt adhesive machine (single roll type), hot melt adhesive machine

600 type pearl cotton hot melt adhesive machine (single roll type), hot melt adhesive machine

Automatic feeding four column hydraulic cutting machine (new single-sided/double-sided automatic feeding), punch press

Automatic feeding four column hydraulic cutting machine (new single-sided/double-sided automatic feeding), punch press

We have the most complete production equipment, including lathes, large milling machines, gantry milling machines, drilling machines, wire cutting machines, large boring machines, CNC machining centers, laser engraving and other processing equipment, to meet the company's mechanical production needs; TAG3TAG42、 Professional R&D team; TAG5TAG63、 Establish an independent laboratory for potential customers to test machines; TAG7TAG84、 We have an office in Kunshan, Jiangsu with high filling mixing machines for customers in East China to test machines and formulas. Address: 1st Floor, Mojian Electronics Factory, No. 638 Huayuan Road, Zhangpu Town, Kunshan City, Jiangsu Province; TAG9TAG105、 Equipment configuration: Taiwanese brands, Japanese brands, German brands, and well-known domestic brands. The brand configuration directly determines the service life of the internal mixer; TAG11TAG126、 Equipment features: Most of them are equipped with variable frequency speed regulation, fast heating system, PLC program control system, inert gas protection device, customized equipment appearance color, determining the mixing chamber and rotor process according to material conditions, temperature control system, and timing and temperature control function; TAG13TAG147、 Changfengte has launched a continuous internal mixer (double rotor continuous internal mixer) for colorants, flame retardants, modified materials, elastomers, and other materials. This mixer has two mixing rotors, and its working principle is similar to that of an internal mixer, but it continuously feeds and discharges like a twin-screw. After the material is discharged from the mixer, it naturally exhausts (the exhaust effect is very good). Productivity is based on feeding rate. Maintaining a constant feed can increase the rotor speed to obtain greater shear force, or slightly close the discharge door to increase the glue discharge temperature. TAG15TAG168、 Complete after-sales support service, solve problems as soon as possible, and determine the output of the continuous mixer without hesitation; TAG17TAG189、 After experimental comparison and certification by the customer, the rotor design of Changfeng mixer is very reasonable and has good dispersion effect. TAG19TAG2010、 For valuable and sticky materials, Changfeng has launched an open close internal mixer, where the chamber can be fully opened and the rotor can be removed for cleaning; TAG21TAG2211、 Changfeng wants to build its own brand and win reputation. We need to make good equipment. TAG23TAG24TAG25 CF-130LXS

We have the most complete production equipment, including lathes, large milling machines, gantry milling machines, drilling machines, wire cutting machines, large boring machines, CNC machining centers, laser engraving and other processing equipment, to meet the company's mechanical production needs; TAG3TAG42、 Professional R&D team; TAG5TAG63、 Establish an independent laboratory for potential customers to test machines; TAG7TAG84、 We have an office in Kunshan, Jiangsu with high filling mixing machines for customers in East China to test machines and formulas. Address: 1st Floor, Mojian Electronics Factory, No. 638 Huayuan Road, Zhangpu Town, Kunshan City, Jiangsu Province; TAG9TAG105、 Equipment configuration: Taiwanese brands, Japanese brands, German brands, and well-known domestic brands. The brand configuration directly determines the service life of the internal mixer; TAG11TAG126、 Equipment features: Most of them are equipped with variable frequency speed regulation, fast heating system, PLC program control system, inert gas protection device, customized equipment appearance color, determining the mixing chamber and rotor process according to material conditions, temperature control system, and timing and temperature control function; TAG13TAG147、 Changfengte has launched a continuous internal mixer (double rotor continuous internal mixer) for colorants, flame retardants, modified materials, elastomers, and other materials. This mixer has two mixing rotors, and its working principle is similar to that of an internal mixer, but it continuously feeds and discharges like a twin-screw. After the material is discharged from the mixer, it naturally exhausts (the exhaust effect is very good). Productivity is based on feeding rate. Maintaining a constant feed can increase the rotor speed to obtain greater shear force, or slightly close the discharge door to increase the glue discharge temperature. TAG15TAG168、 Complete after-sales support service, solve problems as soon as possible, and determine the output of the continuous mixer without hesitation; TAG17TAG189、 After experimental comparison and certification by the customer, the rotor design of Changfeng mixer is very reasonable and has good dispersion effect. TAG19TAG2010、 For valuable and sticky materials, Changfeng has launched an open close internal mixer, where the chamber can be fully opened and the rotor can be removed for cleaning; TAG21TAG2211、 Changfeng wants to build its own brand and win reputation. We need to make good equipment. TAG23TAG24TAG25 CF-130LXS