Plastic&Elastormer

General Plastic

ABS

Engineering Plastic

PEEK

Fillers and reinforcements

Calcium carbonate

Composite materials and reinforcing fibers

Other composite materials

Pigments and Color Masterbatch

Color Masterbatch

Pigment

Titanium dioxide

Semi finished products

Bar

Industrial Precision Components

additive

Flame retardant

Deodorant for plastics

wax

Other Surfactants

Other Chemicals

Coatings Equipment

Production equipment

Pigment

Azo

Disazo

Phthalocyanine

Phthalocyanine Blue

Polycyclic

Pyrrole

Titanium Dioxide

Rutile

Other

High Reflective

Additive

Antioxidant

Adhesion

Monomer

Acrylic & Acrylate

MMA

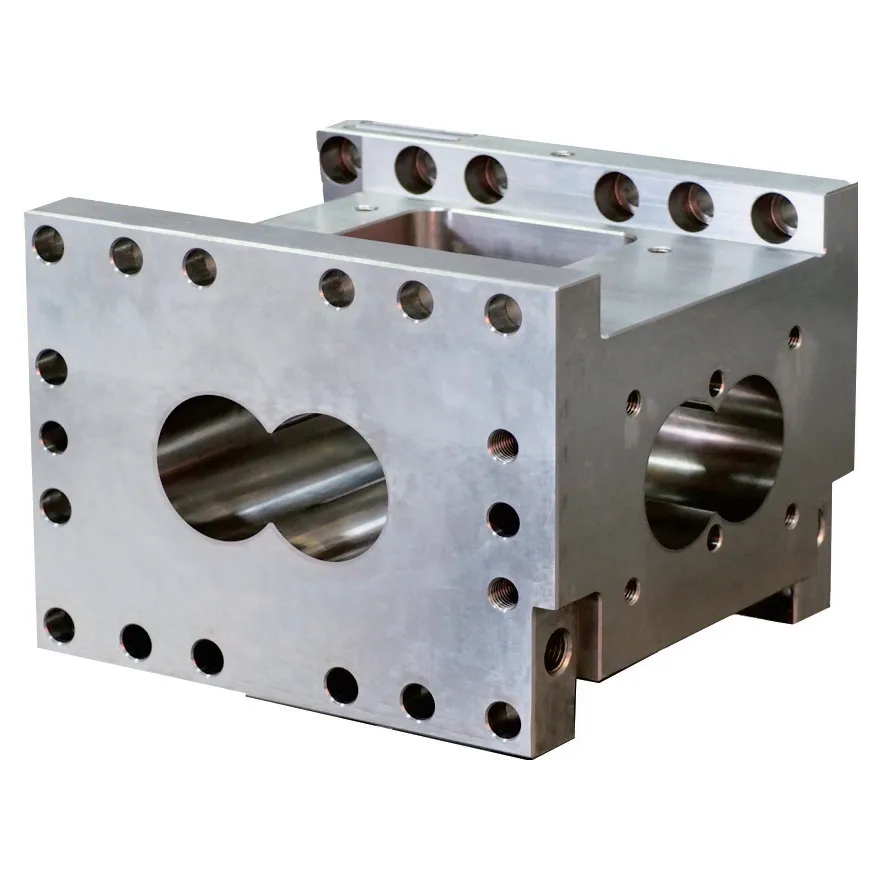

Plastic And Rubber Machinery And Equipment

Measuring and experimental equipment

Experimental equipment

Pre processing and recycling machinery

Pelletizer

Abrasives

hot runner system

Extruders and extrusion lines

Double screw extruder

Other extrusion lines

Aluminum paste 210-30-E1 Sparkle Silvet 760-20-E for American Star Platinum Union plastics

Aluminum paste 210-30-E1 Sparkle Silvet 760-20-E for American Star Platinum Union plastics

Aluminum paste 210-30-E1 Silvet 430-30-E1 for American Star Platinum Union plastics

Aluminum paste 210-30-E1 Silvet 430-30-E1 for American Star Platinum Union plastics

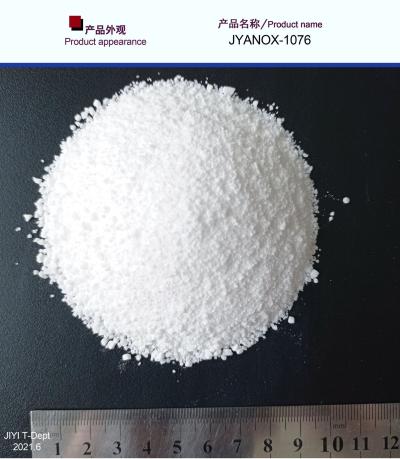

Antioxidant 1076 antioxidant 1076JYANOX-1076Antioxidant1076 for engineering plastics PP

Antioxidant 1076 antioxidant 1076JYANOX-1076Antioxidant1076 for engineering plastics PP

Methyl methacrylate (MMA) is mainly used as a monomer for organic glass and also in the production of other plastics, coatings, etc. by Guangzhou Zuhao Trading Co., Ltd.

Methyl methacrylate (MMA) is mainly used as a monomer for organic glass and also in the production of other plastics, coatings, etc. by Guangzhou Zuhao Trading Co., Ltd.

Attachment enhancer HF-366PABC123ILILTAG0TAG1TAG2 produced TAG3TAG4TAG5TAG6 Product introduction TAG7TAG8TAG9TAG10TAG11TAG11TAG12TAG12TAG13HF-366PTAG14TAG15 is a low chlorinated polyethylene resin TAG16, which is suitable for polyolefin plastics such as TAG18PPTAG19、TAG20TPOTAG21、TAG22PETTAG23、TAG24OPPTAG25、TAG26PATAG27、TAG28PBTTAG29、TAG30SMCTAG31、TAG32EPDMTAG33 Mixing, with better adhesion and special adhesion and pigment wetting properties. TAG34TAG35TAG36TAG37TAG38TAG39TAG40 Product Features TAG41TAG42TAG43TAG44TAG45TAG46TAG47 Group TAG48TAG49& nbsp; TAG50TAG51 becomes TAG52TAG53& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG54TAG55 modified chlorinated polypropylene TAG56TAG57TAG58TAG59TAG60TAG61 external TAG62TAG63& nbsp; TAG64TAG65 View TAG66TAG67& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG68TAG69 slightly yellow particles TAG70TAG71TAG72TAG73TAG74TAG75 non-volatile matter TAG76TAG77& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG78100% TAG79TAG80TAG81TAG82TAG83 Chlorine content TAG84TAG85& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG8630TAG87 ± TAG882% TAG89TAG90TAG91TAG92TAG93 adhesive TAG94TAG95& nbsp; TAG96TAG97 degrees: TAG98TAG99& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG100150-300TAG101TAG102TAG103TAG104TAG105 (TAG10625TAG107 ℃ TAG10830% TAG109 toluene solution) TAG110. mpa. sTAG111) TAG112TAG113TAG114TAG115TAG116TAG117TAG118 Application areas TAG119TAG120TAG121TAG122TAG124TAG125HF-366PTAG126TAG127 is mainly used to produce TAG128PPTAG129 silk screen ink, packaging printing ink, high-temperature resistant ink, adhesives and other main materials (tree resin TAG130) TAG131TAG123TAG133TAG133TAG134TAG135TAG136 Main characteristics TAG137TAG138TAG138TAG139TAG140TAG14141TAG142TAG143 · Excellent adhesion to TAG144PPTAG145, TAG146PETTAG147, TAG148ABSTG149, TAG150EPDMTAG151 TAG156TAG157 · Upward The applied paint has excellent adhesion TAG158TAG159TAG160TAG161TAG162TAG163 · Excellent adhesion to the upper layer of ink TAG164TAG165TAG166TAG167TAG168TAG169 · Good chemical resistance, oil resistance, and weather resistance TAG170TAG171TAG172TAG173TAG174TAG175TAG176 Usage TAG177TAG178TAG179TAG180TAG181TAG182TAG183 · Dissolve in aromatic hydrocarbons, ester solvents, etc. before use, and then use TAG184. TAG185TAG186TAG187TAG188TAG189 · Add pigment and grind directly to make the base paint. TAG190TAG191TAG192TAG193TAG194TAG195 · Directly or in combination with resin to make paint or ink, please test the optimal addition amount before use. TAG196TAG197TAG198TAG199TAG200TAG201TAG202 Addition amount TAG203TAG204TAG205TAG206TAG207TAG208TAG209 depends on the coating system. Before use, please test the optimal addition amount TAG210TAG211TAG212TAG213TAG214TAG215TAG216Operation and safety TAG217TAG218TAG219TAG220TAG221TAG222TAG223 Handle with care to avoid contact with skin and eyes. For other information, please refer to the Material Safety Data Sheet. TAG224TAG225TAG226TAG227TAG228TAG229TAG230Storage conditions TAG231TAG232TAG233TAG234TAG235TAG236TAG237 · TAG238TAG239 Keep away from heat and fire sources; TAG240TAG241TAG242TAG243TAG244TAG245 · TAG246TAG247 should be placed in a cool and ventilated place, and the container should be kept tightly sealed; TAG248TAG249TAG250TAG251TAG252253 · TAG254TAG255 Storage environment: TAG260TAG257 ℃ to TAG25840TAG259 ℃ TAG260TAG261TAG262TAG263TAG264TAG265TAG266 Packaging: TAG267TAG268TAG269 Net weight: TAG270TAG2712720kg/TAG272TAG273 Package TAG274TAG275TAG276TAG277TAG278TAG279TAG280TAG281TAG282TAG283TAG284TAG285TAG286TAG287TAG288 Validity period: TAG289TAG290TAG291From the date of production, the shelf life is TAG29212TAG293 months. TAG294TAG295TAG296TAG297

Attachment enhancer HF-366PABC123ILILTAG0TAG1TAG2 produced TAG3TAG4TAG5TAG6 Product introduction TAG7TAG8TAG9TAG10TAG11TAG11TAG12TAG12TAG13HF-366PTAG14TAG15 is a low chlorinated polyethylene resin TAG16, which is suitable for polyolefin plastics such as TAG18PPTAG19、TAG20TPOTAG21、TAG22PETTAG23、TAG24OPPTAG25、TAG26PATAG27、TAG28PBTTAG29、TAG30SMCTAG31、TAG32EPDMTAG33 Mixing, with better adhesion and special adhesion and pigment wetting properties. TAG34TAG35TAG36TAG37TAG38TAG39TAG40 Product Features TAG41TAG42TAG43TAG44TAG45TAG46TAG47 Group TAG48TAG49& nbsp; TAG50TAG51 becomes TAG52TAG53& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG54TAG55 modified chlorinated polypropylene TAG56TAG57TAG58TAG59TAG60TAG61 external TAG62TAG63& nbsp; TAG64TAG65 View TAG66TAG67& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG68TAG69 slightly yellow particles TAG70TAG71TAG72TAG73TAG74TAG75 non-volatile matter TAG76TAG77& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG78100% TAG79TAG80TAG81TAG82TAG83 Chlorine content TAG84TAG85& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG8630TAG87 ± TAG882% TAG89TAG90TAG91TAG92TAG93 adhesive TAG94TAG95& nbsp; TAG96TAG97 degrees: TAG98TAG99& nbsp; & nbsp; & nbsp; & nbsp; & nbsp; TAG100150-300TAG101TAG102TAG103TAG104TAG105 (TAG10625TAG107 ℃ TAG10830% TAG109 toluene solution) TAG110. mpa. sTAG111) TAG112TAG113TAG114TAG115TAG116TAG117TAG118 Application areas TAG119TAG120TAG121TAG122TAG124TAG125HF-366PTAG126TAG127 is mainly used to produce TAG128PPTAG129 silk screen ink, packaging printing ink, high-temperature resistant ink, adhesives and other main materials (tree resin TAG130) TAG131TAG123TAG133TAG133TAG134TAG135TAG136 Main characteristics TAG137TAG138TAG138TAG139TAG140TAG14141TAG142TAG143 · Excellent adhesion to TAG144PPTAG145, TAG146PETTAG147, TAG148ABSTG149, TAG150EPDMTAG151 TAG156TAG157 · Upward The applied paint has excellent adhesion TAG158TAG159TAG160TAG161TAG162TAG163 · Excellent adhesion to the upper layer of ink TAG164TAG165TAG166TAG167TAG168TAG169 · Good chemical resistance, oil resistance, and weather resistance TAG170TAG171TAG172TAG173TAG174TAG175TAG176 Usage TAG177TAG178TAG179TAG180TAG181TAG182TAG183 · Dissolve in aromatic hydrocarbons, ester solvents, etc. before use, and then use TAG184. TAG185TAG186TAG187TAG188TAG189 · Add pigment and grind directly to make the base paint. TAG190TAG191TAG192TAG193TAG194TAG195 · Directly or in combination with resin to make paint or ink, please test the optimal addition amount before use. TAG196TAG197TAG198TAG199TAG200TAG201TAG202 Addition amount TAG203TAG204TAG205TAG206TAG207TAG208TAG209 depends on the coating system. Before use, please test the optimal addition amount TAG210TAG211TAG212TAG213TAG214TAG215TAG216Operation and safety TAG217TAG218TAG219TAG220TAG221TAG222TAG223 Handle with care to avoid contact with skin and eyes. For other information, please refer to the Material Safety Data Sheet. TAG224TAG225TAG226TAG227TAG228TAG229TAG230Storage conditions TAG231TAG232TAG233TAG234TAG235TAG236TAG237 · TAG238TAG239 Keep away from heat and fire sources; TAG240TAG241TAG242TAG243TAG244TAG245 · TAG246TAG247 should be placed in a cool and ventilated place, and the container should be kept tightly sealed; TAG248TAG249TAG250TAG251TAG252253 · TAG254TAG255 Storage environment: TAG260TAG257 ℃ to TAG25840TAG259 ℃ TAG260TAG261TAG262TAG263TAG264TAG265TAG266 Packaging: TAG267TAG268TAG269 Net weight: TAG270TAG2712720kg/TAG272TAG273 Package TAG274TAG275TAG276TAG277TAG278TAG279TAG280TAG281TAG282TAG283TAG284TAG285TAG286TAG287TAG288 Validity period: TAG289TAG290TAG291From the date of production, the shelf life is TAG29212TAG293 months. TAG294TAG295TAG296TAG297

S wax flakes Licowax SABC123ILILTAG0TAG1Licowax S TAG2 flakes are an acid wax widely used in various applications, such as external release agents (such as for thermosetting and engineering plastics), emulsifiers (such as for paraffin wax), and additives in care products (for their protection and gloss properties). TAG3TAG4TAG5TAG6 ™ TAG7RBW VitaTAG8 is a sustainable bio based wax, derived from renewable rice bran oil and a byproduct of rice processing. TAG9TAG10TAG11TAG12 provides similar functionality while achieving sustainability goals. Contact us for more information or to request a sample. TAG13TAG14TAG15TAG16TAG17 Advantages TAG18TAG19TAG20TAG21TAG22High polarity TAG23TAG24TAG25TAG26 Easy to operate and emulsify TAG27TAG28TAG29TAG30 Protection and gloss performance TAG31TAG32TAG33TAG34 Release attributes TAG35TAG36TAG37TAG38 Auxiliary emulsification TAG39TAG41TAG42TAG43 Technical specifications TAG44TAG45TAG46TAG47TAG48TAG49TAG50TAG51TAG52TAG53TAG54TAG55TAG56TAG57TAG58TAG59 The application TAG60TAG61TAG62TAG63TAG64 mainly serves as an external release agent. The protection and gloss properties of polishing emulsion help to emulsify TAG65TAG66TAG67TAG68 with paraffin, disperse pigments TAG69TAG70TAG71 packaging and handling TAG72TAG73TAG74TAG75TAG76TAG77 delivery form TAG78TAG79TAG80TAG81TAG82 sheet TAG83TAG84TAG85 packaging TAG86TAG87TAG88TAG89TAG90 polyethylene bag TAG9120 kgTAG92TAG93TAG94 tray TAG951000 kg (50TAG96 bag) TAG97TAG98TAG99 storage TAG100TAG101TAG102TAG103TAG104TAG105TAG106TAG107TAG108TAG109TAG110TAG111TAG112TAG113TAG114 To achieve the best shelf life, store the product in a dry area at normal ambient temperature. The minimum shelf life is two years from the date of storage. TAG115TAG116TAG117

S wax flakes Licowax SABC123ILILTAG0TAG1Licowax S TAG2 flakes are an acid wax widely used in various applications, such as external release agents (such as for thermosetting and engineering plastics), emulsifiers (such as for paraffin wax), and additives in care products (for their protection and gloss properties). TAG3TAG4TAG5TAG6 ™ TAG7RBW VitaTAG8 is a sustainable bio based wax, derived from renewable rice bran oil and a byproduct of rice processing. TAG9TAG10TAG11TAG12 provides similar functionality while achieving sustainability goals. Contact us for more information or to request a sample. TAG13TAG14TAG15TAG16TAG17 Advantages TAG18TAG19TAG20TAG21TAG22High polarity TAG23TAG24TAG25TAG26 Easy to operate and emulsify TAG27TAG28TAG29TAG30 Protection and gloss performance TAG31TAG32TAG33TAG34 Release attributes TAG35TAG36TAG37TAG38 Auxiliary emulsification TAG39TAG41TAG42TAG43 Technical specifications TAG44TAG45TAG46TAG47TAG48TAG49TAG50TAG51TAG52TAG53TAG54TAG55TAG56TAG57TAG58TAG59 The application TAG60TAG61TAG62TAG63TAG64 mainly serves as an external release agent. The protection and gloss properties of polishing emulsion help to emulsify TAG65TAG66TAG67TAG68 with paraffin, disperse pigments TAG69TAG70TAG71 packaging and handling TAG72TAG73TAG74TAG75TAG76TAG77 delivery form TAG78TAG79TAG80TAG81TAG82 sheet TAG83TAG84TAG85 packaging TAG86TAG87TAG88TAG89TAG90 polyethylene bag TAG9120 kgTAG92TAG93TAG94 tray TAG951000 kg (50TAG96 bag) TAG97TAG98TAG99 storage TAG100TAG101TAG102TAG103TAG104TAG105TAG106TAG107TAG108TAG109TAG110TAG111TAG112TAG113TAG114 To achieve the best shelf life, store the product in a dry area at normal ambient temperature. The minimum shelf life is two years from the date of storage. TAG115TAG116TAG117

EVA foam requires high fineness, uniform dispersion, and excellent properties such as no black spots, no large uneven pores, no discoloration, and no migration. Our company has achieved breakthrough results in the dispersion of EVA foam using secondary separation technology after multiple experiments. It is specifically used for EVA and polyurethane foam. Recommended use: H0901A, H0902A, H08, etc. Main uses: 1. Coloring (blue phase with red light) 2 Whitening (equivalent to the effect of whitening agents) application scope: color masterbatch, plastics, coatings, paints, inks, leather, art pigments, cosmetics, etc.

EVA foam requires high fineness, uniform dispersion, and excellent properties such as no black spots, no large uneven pores, no discoloration, and no migration. Our company has achieved breakthrough results in the dispersion of EVA foam using secondary separation technology after multiple experiments. It is specifically used for EVA and polyurethane foam. Recommended use: H0901A, H0902A, H08, etc. Main uses: 1. Coloring (blue phase with red light) 2 Whitening (equivalent to the effect of whitening agents) application scope: color masterbatch, plastics, coatings, paints, inks, leather, art pigments, cosmetics, etc.

Pigment Red 170 F5RKAB123HILL Pigment Red 170/Eternal Red F5RK C.I.NO: Pigment Red 170 CAS Number: 2786-76-7 Molecular Weight: 454.48 Molecular Formula: C26H22N4O4 Performance and Application: Blue Light Red. Blue light red powder. Insoluble in water, acid and alkali resistant. It is generally insoluble in organic solvents and has good fastness. There are two types of crystals in this structure. Suitable for advanced coating applications, mainly used for tools, automotive coatings, and equipment manufacturing coatings. It can also be used for PVC ink and packaging printing coatings. This product uses polypropylene, viscose fiber, and vinegar for protoplast coloring. Suitable for coloring PVC and PE plastics

Pigment Red 170 F5RKAB123HILL Pigment Red 170/Eternal Red F5RK C.I.NO: Pigment Red 170 CAS Number: 2786-76-7 Molecular Weight: 454.48 Molecular Formula: C26H22N4O4 Performance and Application: Blue Light Red. Blue light red powder. Insoluble in water, acid and alkali resistant. It is generally insoluble in organic solvents and has good fastness. There are two types of crystals in this structure. Suitable for advanced coating applications, mainly used for tools, automotive coatings, and equipment manufacturing coatings. It can also be used for PVC ink and packaging printing coatings. This product uses polypropylene, viscose fiber, and vinegar for protoplast coloring. Suitable for coloring PVC and PE plastics

EVA foam requires high fineness, uniform dispersion, and excellent properties such as no black spots, no large uneven pores, no discoloration, and no migration. Our company has achieved breakthrough results in the dispersion of EVA foam using secondary separation technology after multiple experiments. It is specifically used for EVA and polyurethane foam. Recommended use: H0901A, H0902A, H08, etc. Main uses: 1. Coloring (blue phase with red light) 2 Whitening (equivalent to the effect of whitening agents) application scope: color masterbatch, plastics, coatings, paints, inks, leather, art pigments, cosmetics, etc.

EVA foam requires high fineness, uniform dispersion, and excellent properties such as no black spots, no large uneven pores, no discoloration, and no migration. Our company has achieved breakthrough results in the dispersion of EVA foam using secondary separation technology after multiple experiments. It is specifically used for EVA and polyurethane foam. Recommended use: H0901A, H0902A, H08, etc. Main uses: 1. Coloring (blue phase with red light) 2 Whitening (equivalent to the effect of whitening agents) application scope: color masterbatch, plastics, coatings, paints, inks, leather, art pigments, cosmetics, etc.

Baixinglian RP-69AC123HILLBersilion RP-69 is a high-end rutile titanium dioxide pigment designed specifically for the plastic industry with a chloride based single aluminum coating. Its particle size has been optimized to provide excellent brightness, high coverage, and high blue phase. By adopting organic treatment, excellent dispersibility and processing performance are obtained in various polymers, and it has good flowability and low oil absorption. After testing, the comprehensive indicators of RP-69 are significantly better than similar imported products. Product features: Excellent blue phase; High whiteness and gloss; High coverage power; Excellent dispersibility application areas: masterbatch; Engineering plastics; Hard and soft PVC plastics; Hard and Soft Pipe

Baixinglian RP-69AC123HILLBersilion RP-69 is a high-end rutile titanium dioxide pigment designed specifically for the plastic industry with a chloride based single aluminum coating. Its particle size has been optimized to provide excellent brightness, high coverage, and high blue phase. By adopting organic treatment, excellent dispersibility and processing performance are obtained in various polymers, and it has good flowability and low oil absorption. After testing, the comprehensive indicators of RP-69 are significantly better than similar imported products. Product features: Excellent blue phase; High whiteness and gloss; High coverage power; Excellent dispersibility application areas: masterbatch; Engineering plastics; Hard and soft PVC plastics; Hard and Soft Pipe

The box type resistance furnace for measuring the content of plastic glass fiber is a new generation of high-performance, mechatronics integrated energy-saving intelligent product. Mainly used for detecting the content of materials such as plastics and fiberglass. It is an ideal equipment for plastic processing, production enterprises, scientific research departments, and colleges. This device can achieve intelligent segmented control of time and temperature.

The box type resistance furnace for measuring the content of plastic glass fiber is a new generation of high-performance, mechatronics integrated energy-saving intelligent product. Mainly used for detecting the content of materials such as plastics and fiberglass. It is an ideal equipment for plastic processing, production enterprises, scientific research departments, and colleges. This device can achieve intelligent segmented control of time and temperature.

Beijing Hanbo Weiye Technology Development Co., Ltd., which has been engaged in the production of fluorescent whitening agents for 20 years, and Jiangxi Beishida Industrial Co., Ltd., which has been engaged in the production and operation of fluorescent whitening agents for 15 years, formed a joint venture in 2014. The strong alliance between the two companies greatly enhances their competitive strength in the fluorescent whitening agent industry. To ensure product quality, the company has invested heavily in purchasing advanced equipment and technological upgrades. Currently, it has advanced production equipment and processes for automatic weighing, automatic feeding, automatic temperature control, and automatic reaction time control. It has widely used super dispersants, high-speed sand mills, and supporting pulp making equipment, as well as advanced testing methods to ensure product quality indicators. The quality of various fluorescent whitening agents has reached the advanced level in China. Practice has shown that compounding technology is still an effective means to improve the whitening effect at present. Highly valuing and addressing the treatment of three wastes is a necessary condition for the survival of enterprises. The company adheres to the path of relying on technological progress for development, collaborates with domestic universities and research institutes, and is committed to introducing, digesting, absorbing, and continuously developing and producing environmentally friendly new products with high-tech content, high added value, and energy conservation and emission reduction. The company has over 100 varieties of various whitening agent series products, including printing and dyeing, plastics, synthetic fibers, water-based coatings, inks, etc., with an annual output of 1200-1500 tons of fluorescent whitening powder products and 2000-2500 tons of slurry fluorescent whitening agent products (non water soluble). We warmly welcome both new and old households from home and abroad to come and discuss cooperation.

Beijing Hanbo Weiye Technology Development Co., Ltd., which has been engaged in the production of fluorescent whitening agents for 20 years, and Jiangxi Beishida Industrial Co., Ltd., which has been engaged in the production and operation of fluorescent whitening agents for 15 years, formed a joint venture in 2014. The strong alliance between the two companies greatly enhances their competitive strength in the fluorescent whitening agent industry. To ensure product quality, the company has invested heavily in purchasing advanced equipment and technological upgrades. Currently, it has advanced production equipment and processes for automatic weighing, automatic feeding, automatic temperature control, and automatic reaction time control. It has widely used super dispersants, high-speed sand mills, and supporting pulp making equipment, as well as advanced testing methods to ensure product quality indicators. The quality of various fluorescent whitening agents has reached the advanced level in China. Practice has shown that compounding technology is still an effective means to improve the whitening effect at present. Highly valuing and addressing the treatment of three wastes is a necessary condition for the survival of enterprises. The company adheres to the path of relying on technological progress for development, collaborates with domestic universities and research institutes, and is committed to introducing, digesting, absorbing, and continuously developing and producing environmentally friendly new products with high-tech content, high added value, and energy conservation and emission reduction. The company has over 100 varieties of various whitening agent series products, including printing and dyeing, plastics, synthetic fibers, water-based coatings, inks, etc., with an annual output of 1200-1500 tons of fluorescent whitening powder products and 2000-2500 tons of slurry fluorescent whitening agent products (non water soluble). We warmly welcome both new and old households from home and abroad to come and discuss cooperation.