Plastic&Elastormer

General Plastic

ABS

Engineering Plastic

PEEK

Fillers and reinforcements

Calcium carbonate

Composite materials and reinforcing fibers

Other composite materials

Pigments and Color Masterbatch

Color Masterbatch

Pigment

Titanium dioxide

Semi finished products

Bar

Industrial Precision Components

additive

Flame retardant

Deodorant for plastics

wax

Other Surfactants

Other Chemicals

Coatings Equipment

Production equipment

Pigment

Azo

Disazo

Phthalocyanine

Phthalocyanine Blue

Polycyclic

Pyrrole

Titanium Dioxide

Rutile

Other

High Reflective

Additive

Antioxidant

Adhesion

Monomer

Acrylic & Acrylate

MMA

Plastic And Rubber Machinery And Equipment

Measuring and experimental equipment

Experimental equipment

Pre processing and recycling machinery

Pelletizer

Abrasives

hot runner system

Extruders and extrusion lines

Double screw extruder

Other extrusion lines

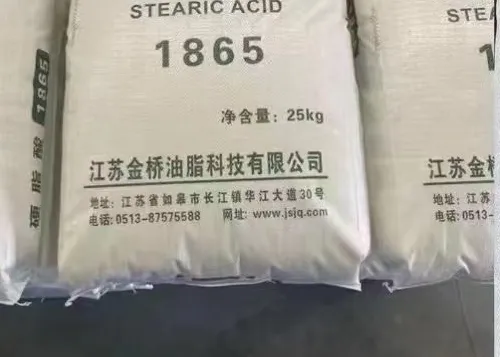

Stearic acid 1865AC123HILL is an important chemical raw material and additive, composed mainly of saturated fatty acids of C16 to C18, with general chemical properties of organic acids Widely used in food, plastics such as rubber, tires, cosmetics, cold resistant plasticizers for plastics, release agents, stabilizers, surfactants, rubber vulcanization accelerators, waterproofing agents, polishing agents, metal soaps, metal mineral flotation agents, softeners (pharmaceuticals and other organic chemicals). It can also be used as a solvent for oil soluble pigments, wax crayon lubricant, wax paper polisher, etc.

Stearic acid 1865AC123HILL is an important chemical raw material and additive, composed mainly of saturated fatty acids of C16 to C18, with general chemical properties of organic acids Widely used in food, plastics such as rubber, tires, cosmetics, cold resistant plasticizers for plastics, release agents, stabilizers, surfactants, rubber vulcanization accelerators, waterproofing agents, polishing agents, metal soaps, metal mineral flotation agents, softeners (pharmaceuticals and other organic chemicals). It can also be used as a solvent for oil soluble pigments, wax crayon lubricant, wax paper polisher, etc.

Jiangsu Yule Machinery Equipment Co., Ltd. is located in Gaogang District, Taizhou City, Jiangsu Province, adjacent to Ningtong Expressway for 5 kilometers to the north and Taizhou Yangtze River Bridge to the south. It faces Suzhou, Wuxi, and Changzhou across the river and is half an hour away from Suzhong Airport. The transportation by land, water, and air is extremely convenient, providing excellent conditions for the company's development. The company has always been committed to building a research and production base for cold granulators, producing various models and specifications of granulators. The LQ25-2000 series cold granulator is a combination product of single screw and twin-screw extruders, widely used for cold drawing and granulation of various plastics. It is mainly used for glass fiber reinforcement and cold drawing granulation of polyolefins, engineering plastics, PP, PBT, PET and other plastics. The company integrates independent development, research and production, with first-class R&D and production capabilities, a professional R&D design team, a scientific quality management execution system, and advanced production equipment. In recent years, the performance parameters of the granulator have been comprehensively upgraded, with a more scientific and reasonable design, making it easier for users to operate, greatly improving the professional performance and safety factor of the product.

Jiangsu Yule Machinery Equipment Co., Ltd. is located in Gaogang District, Taizhou City, Jiangsu Province, adjacent to Ningtong Expressway for 5 kilometers to the north and Taizhou Yangtze River Bridge to the south. It faces Suzhou, Wuxi, and Changzhou across the river and is half an hour away from Suzhong Airport. The transportation by land, water, and air is extremely convenient, providing excellent conditions for the company's development. The company has always been committed to building a research and production base for cold granulators, producing various models and specifications of granulators. The LQ25-2000 series cold granulator is a combination product of single screw and twin-screw extruders, widely used for cold drawing and granulation of various plastics. It is mainly used for glass fiber reinforcement and cold drawing granulation of polyolefins, engineering plastics, PP, PBT, PET and other plastics. The company integrates independent development, research and production, with first-class R&D and production capabilities, a professional R&D design team, a scientific quality management execution system, and advanced production equipment. In recent years, the performance parameters of the granulator have been comprehensively upgraded, with a more scientific and reasonable design, making it easier for users to operate, greatly improving the professional performance and safety factor of the product.

Our company's gantry granulator series products are suitable for cold drawn cutting of various thermoplastic general engineering plastics and modified engineering plastics, such as ABS, PA, PBT, PC, PE, PET, POM, PP, PPS, PS, PVC, SAN, etc., including glass fiber reinforced and inorganic filled thermoplastic extruded strips. It can be used in conjunction with various small and medium-sized single and twin-screw extruders. After being cooled by a cooling water tank, a cooling conveyor belt, an air knife or an air duct, the material strip enters the feeding port of the granulator and is forcibly fed between the fixed knife and the moving knife by a traction roller for particle cutting.

Our company's gantry granulator series products are suitable for cold drawn cutting of various thermoplastic general engineering plastics and modified engineering plastics, such as ABS, PA, PBT, PC, PE, PET, POM, PP, PPS, PS, PVC, SAN, etc., including glass fiber reinforced and inorganic filled thermoplastic extruded strips. It can be used in conjunction with various small and medium-sized single and twin-screw extruders. After being cooled by a cooling water tank, a cooling conveyor belt, an air knife or an air duct, the material strip enters the feeding port of the granulator and is forcibly fed between the fixed knife and the moving knife by a traction roller for particle cutting.

Our company produces various granulation equipment for recycling plastics, including PVC, WPC, PE/PP, and PET. By using different granulation processes, such as ground granulation, water ring granulation, strip granulation, and underwater granulation, various waste plastics with different physical properties are processed into plastic pellets that can be reused to achieve the goal of recycling and environmental protection. Our company's products have undergone long-term factory production certification, and the production equipment adopts imported electrical appliances with reasonable structure, simple operation, reliable and durable quality. High particle recycling yield, high cleanliness, beautiful and plump particles, deeply loved by customers.

Our company produces various granulation equipment for recycling plastics, including PVC, WPC, PE/PP, and PET. By using different granulation processes, such as ground granulation, water ring granulation, strip granulation, and underwater granulation, various waste plastics with different physical properties are processed into plastic pellets that can be reused to achieve the goal of recycling and environmental protection. Our company's products have undergone long-term factory production certification, and the production equipment adopts imported electrical appliances with reasonable structure, simple operation, reliable and durable quality. High particle recycling yield, high cleanliness, beautiful and plump particles, deeply loved by customers.

We offer semi-finished products made of various engineering plastics such as PA/POM/PET/PEI/PEEK for bar

We offer semi-finished products made of various engineering plastics such as PA/POM/PET/PEI/PEEK for bar

Based on years of experience in the application of hot runner systems, Nanfeng has developed locally produced hot runner systems to meet the cost, delivery time, and quality requirements of our customers. We have established rigorous quality objectives for our developed hot runner products, aligning with leading brands in the industry in terms of design, material selection, and production control. We are committed to providing users with cost-effective and high-quality products. The Nanfeng hot runner is divided into three series: Q2, Q3, and Q4, corresponding to different injection molding requirements and nozzle installation diameters. Q2 corresponds to a small injection volume and installation space, and is also widely used in packaging applications. Q3 corresponds to general injection molding requirements and is suitable for high injection pressure applications (thin-walled). Each series of Nanfeng hot runner nozzles can also choose different injection port methods to meet various injection molding requirements. Based on our years of application experience, the design of Nanfeng hot runner takes functionality and practicality as the main considerations, and is suitable for most plastics. We insist on using high-quality raw materials to ensure the quality of the system. All electric heating elements are imported from Europe and America. The production process has our rigorous control, and all products meet our quality standards. Q4 corresponds to larger requirements for injection molded products.

Based on years of experience in the application of hot runner systems, Nanfeng has developed locally produced hot runner systems to meet the cost, delivery time, and quality requirements of our customers. We have established rigorous quality objectives for our developed hot runner products, aligning with leading brands in the industry in terms of design, material selection, and production control. We are committed to providing users with cost-effective and high-quality products. The Nanfeng hot runner is divided into three series: Q2, Q3, and Q4, corresponding to different injection molding requirements and nozzle installation diameters. Q2 corresponds to a small injection volume and installation space, and is also widely used in packaging applications. Q3 corresponds to general injection molding requirements and is suitable for high injection pressure applications (thin-walled). Each series of Nanfeng hot runner nozzles can also choose different injection port methods to meet various injection molding requirements. Based on our years of application experience, the design of Nanfeng hot runner takes functionality and practicality as the main considerations, and is suitable for most plastics. We insist on using high-quality raw materials to ensure the quality of the system. All electric heating elements are imported from Europe and America. The production process has our rigorous control, and all products meet our quality standards. Q4 corresponds to larger requirements for injection molded products.